HEAVY DUTY RANGE

With over 10 heavy duty models in its line-up, the Hino 700 Series heavy duty range gets the job done. It has the ultimate combination of Japanese engineering, build quality, levels of standard safety equipment and lifesaving technologies.

The 700 Series has a purpose design driveline employing the ever reliable and efficient Hino 13 litre 440Hp, 450Hp and 480Hp engines.

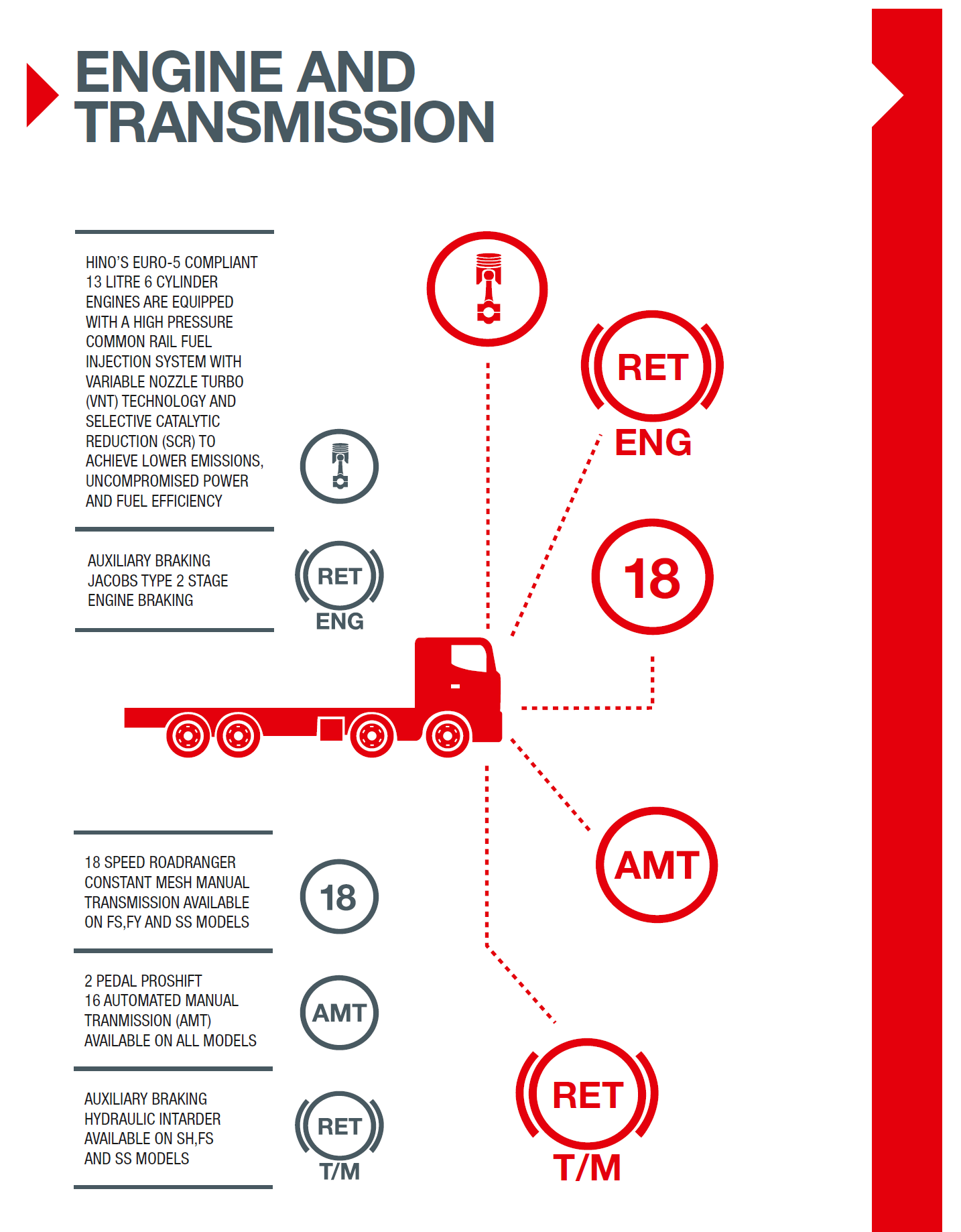

These can be matched to a choice of either an 18 speed Roadranger constant mesh manual transmission or the 2-Pedal ProShift 16, automated manual transmission, fitted standard with an auxiliary braking hydraulic intarder (not available on FY models).

Hino 700 Series buyers have the choice of 4×2, 6×4 and 8×4 driveline configurations, suited to both prime mover and rigid truck applications.

HINO E13 COMMON-RAIL DIESEL ENGINE

Renowned for its long-term durability and reliability, the E13 12.9-litre Hino six-cylinder diesel is not only economical to run, but provides excellent throttle response and torque for heavy duty applications.

Hino 700 Series models are powered by either a 321, 331 or 353 kilowatt variant of the E13 12.9-litre engine.

Fully Euro 5 emission standard compliant, the E13 engine features a Selective Catalytic Reduction (SCR) system, utilising AdBlue as an exhaust treatment to dramatically reduce harmful Nitrous Oxide (NOx) emissions.

EATON RTLO 18 SPEED MANUAL

The world-renowned Eaton RTLO 18 speed transmission is perfectly suited to a wide variety of long-haul heavy duty applications.

With 18 forward gears and four reverse ratios, the constant mesh Eaton box is ideal for use with Hino’s 12.9-litre six cylinder engine.

Available on all Hino 700 Series models (except SH), the Eaton box features full hydraulic clutch control with air booster and 387mm twin dry-place ceramic clutch for long life and maximum durability.

ERGONOMIC CABIN LAYOUT

The Hino 700 Series cabin is one of the most inviting workplaces in the heavy-duty class, boasting class leading features and equipment.

It begins with cabin entry. Enhanced access door steps offer greater ease and safety of entry and exit to the 700 Series. The doors open 90 degrees and the deep grab handles are self-cleaning to prevent slipping in poor weather.

All of Hino’s 700 Series heavy duty trucks have the fully air adjustable ISRI 6860/870 Series seat with fully integrated seat-mounted seatbelt. The seat can be configured to the body type of almost any driver and provides the ultimate in cabin comfort.

Foot and leg space has been further increased by raising the lower edge of the instrument panel. Hino 700 Series’ features include a floor-mounted auto-shift lever, for a more natural shift feel. There’s a new, easy-to-read backlit instrument cluster with multi-information display, improved switch operability and increased storage space.

Storage space includes a wide free rack, bottle holders, convenience hooks and at least two spare DIN spaces in the centre of the dashboard. There’s also door pockets, centre console storage, a centre-seat tray and overhead console.

CORPORATE SOCIAL RESPONSIBILITY (CSR) AND ENVIRONMENT

Hino trucks CSR activities concentrate on the environment and the well-being of its customers, stakeholders, employees and communities worldwide. Our commitment to the environment is manifested throughout all aspects of the business.

Our global vision and principles focus on making a positive contribution by minimising environmental impact, while focusing on sustainable development. Concern for the global environment has made Hino a leader in advanced diesel engine and emissions technologies.

WORLD LEADER IN COMMERCIAL VEHICLE HYBRID TECHNOLOGY

Since its local launch in 2007, the Hino Hybrid low emission range of trucks has been the clear market leader in Hybrid commercial vehicle sales in Australia.

The new generation Hino 300 Series Hybrid features the world’s first Hybrid diesel engine designed exclusively for a commercial vehicle, delivering cleaner, more efficient transport solutions.

Lower exhaust emissions mean cleaner air. By employing a diesel electric Hybrid system, using an auxiliary electric motor that is emission-free, the Hino Hybrid drive system significantly reduces exhaust tailpipe emissions when compared to a conventional diesel-engine truck.

Compared to a conventional truck, the Hino Hybrid emits significantly reduced emissions of carbon monoxide, carbon dioxide, particulate matter and nitrogen oxide.

Hybrid technology is what Hino Motors currently consider the best suited for commercial vehicles to enhance the environmental performance of trucks and buses.

This is an all round technology that focuses on everything from the distance that can be travelled, loading capacity, to adaptivity for various loading platforms and roles it can perform.

A large proportion of Hino trucks environmental focus is on the curbing of global warming through a reduction in the amount of CO2 emitted by its vehicles.

Hino has improved its existing diesel trucks so they meet and exceed efficiency and emission standards.

Recent research into emission-reductions have included developments in electric light duty trucks, electric small buses, the Melpha plug-in hybrid bus, and the Profia electric refrigeration truck which uses hybrid battery systems for greater efficiency.

CLEANER EMISSIONS

Hino uses Selective Catalytic Reduction (SCR). SCR is an exhaust after treatment system that virtually eliminates harmful oxides of nitrogen (NOx) from exhaust gases.

Mixing NOx from the engine’s exhaust with AdBlue®, a solution containing ammonia (NH3) produces nitrogen (N2) and small amounts of CO2 as a result.

This system fully complies with the current Australian emission standard by converting nearly all harmful exhaust gas emission into harmless nitrogen (N2) and water vapour (H2O).

Hino also uses a Diesel Particulate active Reduction system (DPR) which captures diesel particulates (soot) and incinerates them (regeneration) preventing their discharge into the atmosphere.

DPR is a proactive exhaust filtration system which automatically self-cleans and traps over 95% of the exhaust carbon soot in a ceramic filter while also reducing the need for manual regeneration.